ABOUT US

OUR MISSION

Our mission is to decarboniSe, decentraliSe, and DEMOCRATISE the processing of critical minerals

Our Story & Technology

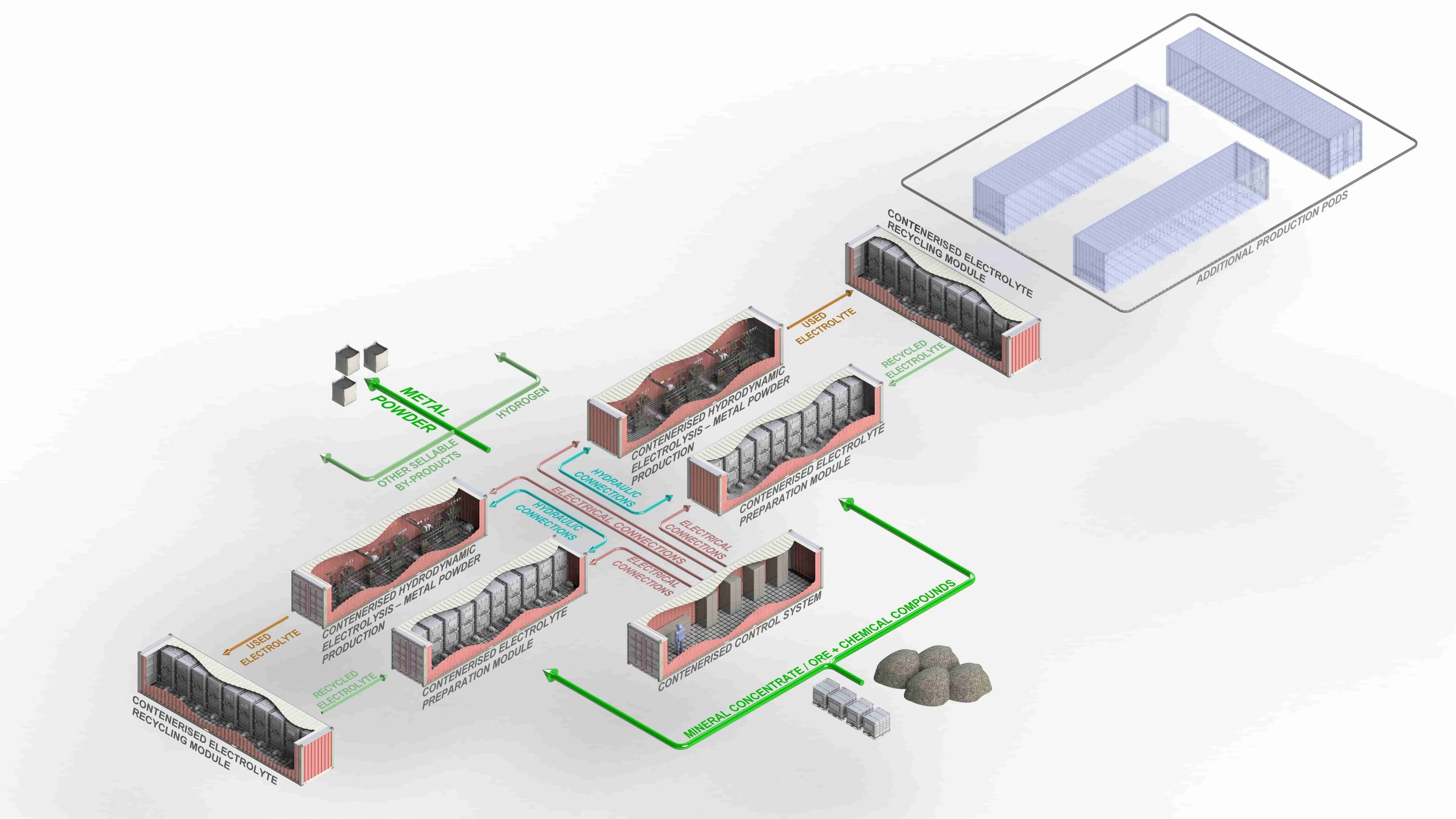

With over 20 years of experience in designing, building, implementing, and scaling industrial prototypes and manufacturing lines, we have developed a novel technology to process critical minerals—from mining output (concentrates, ore, and waste) to high-purity metal powders—in a single modular production line powered by renewable energy.

OUR APPROACH

Our Breakthrough approach

The Challenge with Traditional Methods

Traditional metal processing relies on high-energy methods that emit significant greenhouse gases, require costly infrastructure, and generate waste.

Our Innovation

Renesis has developed a groundbreaking low-temperature hydrodynamic electrolysis solution that produces high-purity metal powders directly from ores, concentrates, or mining waste at just 45–70°C. This innovation drastically reduces energy consumption and minimises waste.

Simplified, Single-Step Production

Our solution eliminates multiple production stages—including roasting, smelting, refining, and atomization—by completing the entire process in a single production line.

Built for Global Deployment

Modular plants can be deployed near mining sites or off-take sites, bypassing jurisdictional challenges and ensuring geopolitical security for critical metal off-takers.

We design and manufacture our processing plants in-house, along with other specialized machines, systems, and production lines. By integrating expertise in mechanical engineering, automation, and chemical engineering, we deliver turnkey solutions—built from the ground up.