mineral processing

MINERAL PROCESSING

Introducing Our Breakthrough Technology

Renesis has developed a groundbreaking solution using low-temperature hydrodynamic electrolysis to produce high-purity, spherical metal powders directly from ores, mining concentrates, and waste or scrap—bypassing smelting, refining, and atomisation, and making the process geopolitically secure. Key milestones include the development of a driving simulator for disabled individuals in 2016

Operating at just 45–70°C, this innovative approach:

Significantly reduces energy consumption

Fully electrifies critical minerals processing

Enables the use of renewable energy for a cleaner, more sustainable supply chain

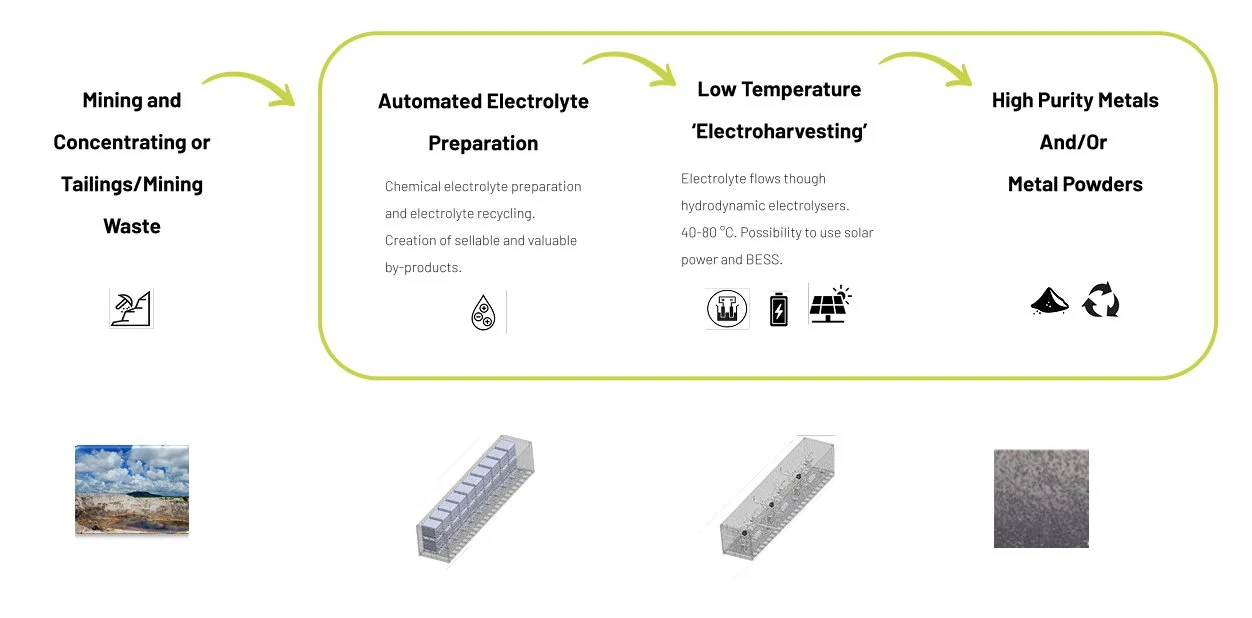

how the technology works

At the core of this breakthrough is a novel hydrodynamic electrolyser, which enables the extraction of high-purity metal powder with fully controlled and tailored morphology, directly beneath the cathode. This eliminates multiple production stages by consolidating them into a single, efficient production line.

Powered by renewable energy, this nearly emission-free system also recovers valuable by-products, supporting a circular economy. The modular, containerised, plug-and-play plants can be deployed anywhere—bypassing geopolitically risky jurisdictions and creating an opportunity to establish a complete processing supply chain with low initial CAPEX.

ADVANTAGES

THE POWER BEHIND THE PROCESS

Geopolitically Secure

Bypassing geopolitically risky areas. Location independent. Production onsite in one processing line, directly from mining output.

Democratisation & Decentralisation

Multiple processing lines located at the source of feedstock across the country, instead of centralised facilities.

Decarbonisation & Electrification

Renewable energy use and energy storage substituting coking coal or gas, allowing real zero emissions. Process also significanly is less energy intensive.

Circular Economy Contribution

Valuable and sellable by-products and secondary minerals.

Profitable

Lower production costs, as the process requires significantly less energy and fewer production steps

Modular and Easy To Scale

Low initial CAPEX and scalable.